Resources and equipment

|

|

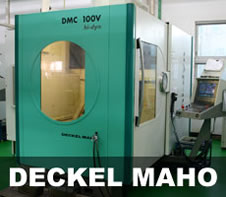

CNC

EDM

|

Dae Han

X: 1200 Y: 800 Z: 500 |

|

Dae Han

X: 500 Y: 400 Z: 350 |

|

|

CHARMILLES

X: 350 Y: 250 Z: 300 |

|

Sodick

X: 550 Y: 400 Z: 300 |

Wire Cut

|

Sodick

X: 750 Y: 500 Z: 500 |

|

Sodick

X: 550 Y: 350 Z: 280 |

CNC lathe Deep Hole Drilling

|

Deckel MaHo

|

|

WIM

X: 1000 Y: 700 Z: 1000 |

CMM

|

Ares (Automatic)

X: 1000 Y: 500 Z: 400 |

|

Mitsutoyo (Manual)

X: 500 Y: 700 Z: 400 |

|

|

COMET®LED

3D scanner

|

|

HandySCAN3D

3D scanner

|

|

|

CHOTEST

SuperView WX100

|

|

Tryout equipmen

|

Equipped 50-1400 ton. The injection molding machine. |

|

HAI TIAN

14000KN Turntable multi-color Plastic machine |

|

ENGEL

1000KN Turntable multi-color Plastic machine |

|

Without drawing workshop

Design of drawings.

drawing workshop. |

3D Printing device

|

Plastic 3D Printer

|

|

Metal 3D Printer

|